We intervene on the development and validation phases of your powertrains (architecture definition, dimensioning, specification, calibration, characterization and endurance) as well as for their qualifications.

We meet the needs of our clients in terms of validation and/or development of a product or function. Our tests are intended to validate or develop but meet the specific needs of each. In 25% of the consultations, we build the specifications of the tests that will allow the objective to be reached.

For each request, we review the suitability of our test benches and our control and acquisition interfaces with the objective set, we jointly determine the key elements to be controlled and the validation criteria.

Within the framework of the electric vehicle, our servicesmeet your needs for complete powertrains and the equipment and sub-assemblies that make them up

Our support is resolutely oriented towards electric mobility: e-motor and battery as part of the development of sustainable mobility solutions.

The Emitech Group offers you its global support in the development and validation of your batteries, relying on the complementary expertise of its teams.

Our main field of activity is the implementation of your test campaigns for characterization and development tests and validation tests (cycling, EMC, vibration, abusive tests …) which takes its full meaning through the battery expertise of our teams.

Upstream, we integrate the type of vehicle for which the battery is intended in order to assist you in the choice of the cell, the design of the modules…

We assist you in the assembly of the battery pack, the design and validation of the BMS (Battery Management System) both from a software and hardware point of view (Model Based Design solutions: SIL – Software in loop and HIL – Harware in Loop).

Our skills in acquisition and piloting (Pulsar solutions) allow us the instrumentation of your batteries for all test campaigns.

All of our support is subject to project management (planning, deliverables, costs, quality, management of complementary solutions).

Among these complementary solutions, we offer you the complete management of the logistics related to your battery (case + ADR transport) as well as recycling.

The Group’s expertise enables us to conduct different test panels

Our new battery cycling bench has been operational since the end of June 2020. It accommodates batteries up to 1.4m in width and more than 2m in length.

It is coupled with a Kratzer battery simulator 250kW / 1000A / 1000Vand is equipped with a CAN BMS-VECTOR monitoring device.

It is coupled with a Kratzer battery simulator 250kW / 1000A / 1000Vand is equipped with a CAN BMS-VECTOR monitoring device.

Its battery flooding device secures the operations.

Technical characteristics:

Our test benches cover the various electrified powertrains: BEV, HEV, PHEV, MHEV...

Our expertise and resources contribute to the development and validation of electric powertrains ranging from micro-hybrids (48V also called mild-hybrids) to 100% electric solutions.

In a thermally controlled environment ranging from -45°C to +120°C, we are able to carry out the characterisation (efficiency, performance) of motors, their inverters and gearboxes, as well as endurance tests on the entire electric drive train.

Our resources allow us to carry out tests ranging from simple electrified components to complete powertrains (BEV, HEV/PHEV, MHEV, etc.)

These tests can be carried out by coupling the machine to be tested to the generator of the test bench or in a back to back configuration in which two electric motors to be tested are connected face to face, one being a generator and the other a receiver. A torque meter and various measurement systems are interposed between the two motors.

Our testing capability is aimed at electrical machines with power ranges up to 250kW with temperature control from -45°C to +120°C for the inverter and rotating machine and -30°C to +120°C for the fluids. The rotating machine can reach a torque of over 500 Nm at low speed (below 6000rpm) and over 20000rpm at high speed.

Banc Electrique CLimatique de cAractérIsation & enduRance :

Total power: 270kW Torque speed: 21krpm and 510Nm up to 6000rpm

Torque speed: 21krpm and 510Nm up to 6000rpm

Mounts up to 21 000 tr

Climatic conditions

Battery Simulator 250kW / 1000V / 1000A

Precision torque measurement range 1000 Nm 22 000 rpm : HBM T12HP

CAN VECTOR card or ETAS equipment with engine control link (INCA)

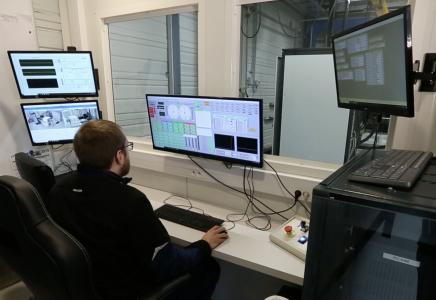

Our own PULSAR control and acquisition software solution is adapted to the specificities of electric motors.

PULSAR manages the safety of our benches and allows the recording at 10Hz of a set of up to 200 measurement channels and thus carries out the piloting of the benches and the fast acquisition of the data of the tested equipment.

Our software suite continues with:

The objective of our tests is to ensure the development and validation of a propulsion system element or sub-assembly. Our test solutions are fully modular and adaptable to your project, whether it concerns innovative propulsion technologies (BEV - electric, HFCV - hydrogen) or more traditional ones (ICE - fuel, HEV/PHEV - hybrid and MHEV - micro-hybrid).

The objective of our tests is to ensure the development and validation of a propulsion system element or sub-assembly. Our test solutions are fully modular and adaptable to your project, whether it concerns innovative propulsion technologies (BEV - electric, HFCV - hydrogen) or more traditional ones (ICE - fuel, HEV/PHEV - hybrid and MHEV - micro-hybrid).

Throughout the definition and management of the tests, we work in project mode. We provide continuous support with our teams and ensure the implementation of all the necessary technical and human support.

Each campaign results in a complete report including: programme, daily monitoring, photographs, measurements, validation criteria and conclusion of the test.

We have a mechanical and electrical expertise centre entirely dedicated to our customers' projects.

We have a mechanical and electrical expertise centre entirely dedicated to our customers' projects.

Mechanical expertise is the last step in the validation tests, allowing us to identify motor failures and validate the architecture at the end of development. We carry out a range of visual, geometric and qualitative measurements to provide a comprehensive survey report.

This expertise applies to batteries through the dismantling of packs in a secure environment.

The Emitech Group has just acquired all of the EMC and electrical testing equipment belonging to the company ExoTest 3E.

This acquisition took effect on 1 January 2026.

Emitech Group - Legal information